| DATA SHEET |

| High Grade Ni-Cr Wire Wound Elements on High Aluminia Ceramic Core |

| Coated With heat Insulating Flame Proof Coating |

| High surge withstanding For Energy Meter |

| Low temp Coefficient High Stability |

| Color Code for Easy identification |

| Standard Tolerance 5% Available |

| Non Inductive type Wire wound Resitors Avaiable on Request |

| Highest Ohmic Values are made as per Customer Requirement. |

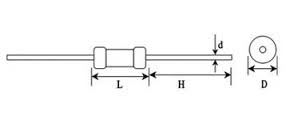

| Style | Dimensions in mm | Power Rating AT 70°C | Resistance Range | |||

| L | D | d | H (min) | |||

| KWR - 0.5 | 6.5±0.5 | 2.3±0.2 | 0.5±0.02 | 27 | 0.5W | 1E - 10E |

| KWR - 1M | 6.5±0.5 | 2.3±0.2 | 0.5±0.02 | 27 | 1W | 1E - 10E |

| KWR - 1 | 9±1 | 3.4±0.5 | 0.52±0.02 | 25 | 1W | 0.1E - 180E |

| KWR - 2 | 12±1 | 5.0±0.5 | 0.60±0.02 | 30 | 2W | 0.01E - 330E |

| KWR - 3 | 16±1 | 5.5±0.5 | 0.68±0.02 | 28 | 3W | 0.01E - 560E |

| KWR - 5 | 18±1 | 6.5±0.5 | 0.78±0.02 | 27 | 5W | 0.01E - 680E |

| KWR - 7 | 21±1 | 7.5±0.5 | 0.78±0.02 | 25 | 7W | 0.01E - 720E |

|

||||||

|

||||||

|

||||||

| Characteristics | Test Methods | Limits | ||||

| D C Resistance | Resistors are tested with standard specified voltages for its Ohmic values to check the specified tolerance. | The Resistors shall be within specified tolerance limits. | ||||

| Short Time Overload | The Resistors shall be subjected to 2.5 times the Rated Voltage or Maximum overload voltage (whichever is low) for a duration of 5 secs. | ? R % = ± 1.0% (+ 0.05 ?) | ||||

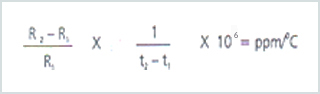

| Temp - Coefficient | The Resistors value shall be checked at 2 temp. i.e. one At Ambient & the final at Amb + 100? C. The TCR is then Calculated as :

|

PPM | ||||

450 Max (Lower PPM on request) |

||||||

| Rated Load | A Rated Continuous Working Voltage or Maximum Wkg. Voltage whichever less shall be applied to the resistors for a duration of 2 Hrs. | ? R % = ± 1.0% Max | ||||

| Solderability | A solder bath is maintained at 230? C. The specimen leads are immersed in the bath & withdrawn within 3 secs. A suitable flux is used during the test. | A fresh solder shall cover the specimen leads by Min. 95% coverage. | ||||

| Resistance to solder heat | A solder bath is maintained at 350? C. The specimen leads are subjected to the bath for a duration of 10 secs. | ? R % = ± 1 % Max | ||||

| Resistance to Solvents | The specimen shall be subjected to IPA for duration of 1 min. 10 strokes of hard brush shall be applied. The test shall be conducted 3 times. | The colour code marking shall remain legible. | ||||

| Die-electric Strength | A foil is wrapped around the specimen body. A voltage of 300 V @ 0.5 ma shall be applied between both the terminals of the specimen for a duration of 1 min. | There shall be no flash over or break down. | ||||

| Terminal Strength | Pull Test: The resistors leads shall be pulled using 5 N force Bend Test: The resistor leads are bend through 180? three times. | There shall be no damage. | ||||

| Load Life | The specimen shall be subjected to an ambient of 70?C for duration of 1000 Hrs. The specimen shall also be loaded for full power dissipation. The duty cycle shall be 1½ Hr. On ½ Hr. Off. | ? R % = ± 5 % Max | ||||

| Steady State Humidity | The shall be subjected to an amb. Of 40?C with RH as 95%, for a duration of 56 days. A small DC voltage shall be so applied that the specimen shall dissipate 1% of the rated power. | ? R % = ± 5 % Max | ||||